Bonded MetPreg Repair for Ships

Reduced Fuel and Maintenance Costs

Aluminum has a density one third that of steel. A ship designed and built with aluminum will have a much lower displacement when compared to the steel. Therefore, smaller engines, reduced fuel and maintenance cost as well as permitting additional mission capability and cargo can be accommodated.

Ships built primarily from aluminum can see fuel savings of over 20%.

The Problem with Aluminum

With all the advantages aluminum ships have, there are a few disadvantages – fatigue cracking, sensitization and corrosion.

As a ship ages, structural components which have undergone cyclic loading for years and perhaps decades begin to form fatigue cracks.

The sensitization of aluminum alloys used in marine applications is a problem of enormous economic significance for both the private and the defense industries. In particular, commonly used magnesium-rich aluminum alloys (5xxx series, high-strength and corrosion resistant) become sensitized when exposed to heat from the sun or from on-board sources. Sensitized aluminum is vulnerable to corrosion, exfoliation, and stress-corrosion cracking. Ultimately, structural failure becomes imminent if the material at high-stress points is sensitized.

And, both fatigue cracking and sensitization is exacerbated by corrosion from the marine environment and from the dissimilar materials from which the ship is manufactured.

The BMR Solution

Touchstone has developed a low-cost, easy repair for many of these situations – BMR, Bonded MetPregTM Repair.

Developed jointly with the Navy, BMR is a simple patch which can be placed over a crack in a structural member providing what is often a permanent repair.

The process involves cleaning around the cracked member and adhesively bonding a patch. There is no welding or bolting, no additional heat and the repairs can be made at sea saving hundreds of thousands of dollars in repair and potentially weeks of downtime for the ship.

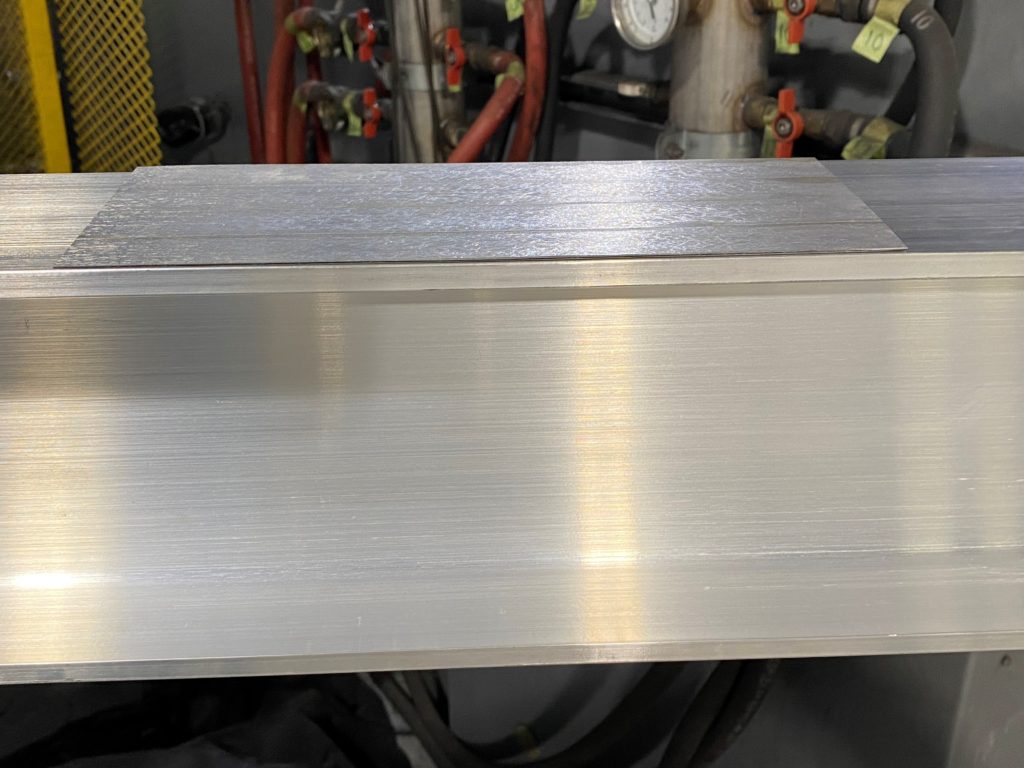

This thin MetPreg patch of the World’s Strongest AluminumTM will carry the load of the top plate of this I-beam.